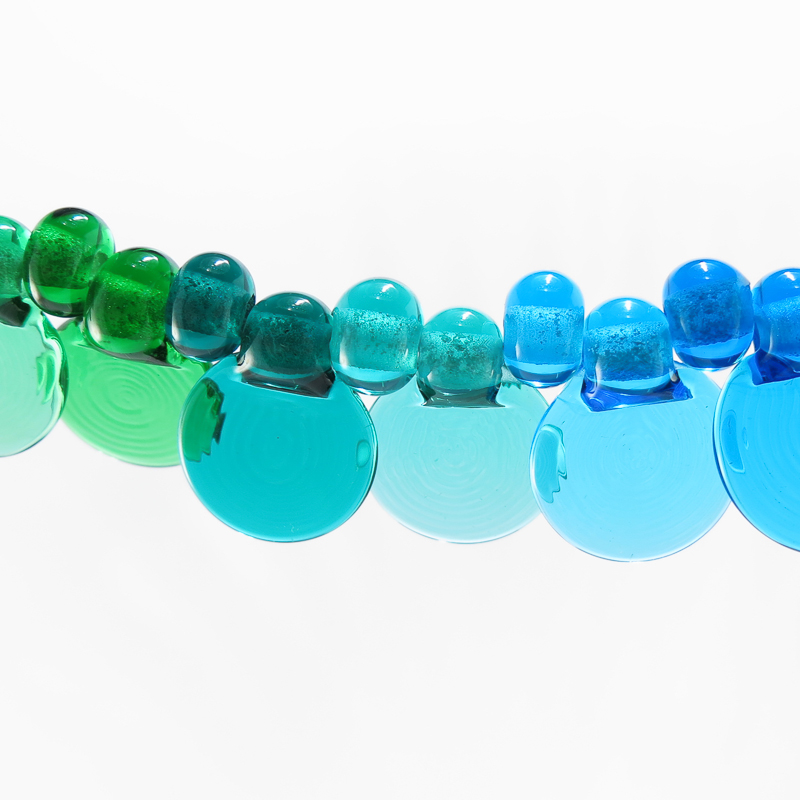

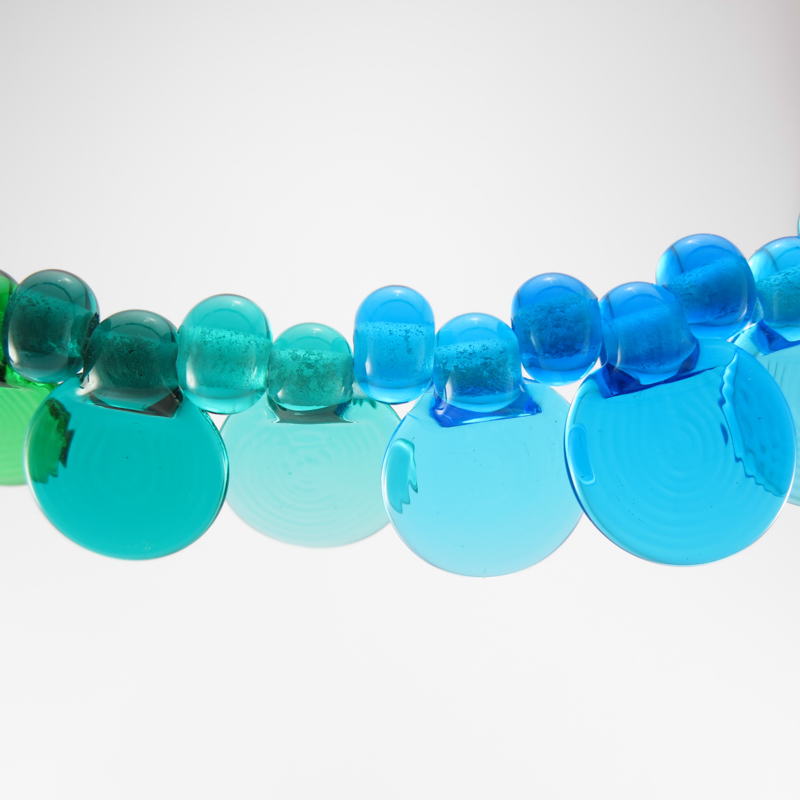

Description

I make every part of my glass surfer bead necklaces myself. I start with a 2mm steel rod dipped in a ceramic paste. This will eventually become the hole in the bead. Then, in a very hot oxygen/propane flameworking torch, I heat up the end of a pencil-sized glass rod until it becomes molten. This liquid glass is carefully stuck to the steel rod which is then turned to wrap the glass around it. In this manner layers of different glass colors are built up to create unique designs.

The whole time there is a dance going on between the turning steel rod, the molten glass and the hot flame. If the bead gets too hot the glass drips off the rod, and too cold it will crack, and the rod can never stop turning or the bead will loose its shape.

Once finished the bead is slowly cooled to relieve stress in the glass and make it strong. Later it’s soaked in water to dissolve the ceramic paste so the bead can be removed from the steel rod and the hole cleaned with a diamond coated reamer.

I source all my materials locally or at least within Europe, and aim to make a product that will last a long time. One of the great things about glass is it lasts a very long time. The earliest beads were made in Egyptian times and are still perfect today, so your bead can be handed down through generations, and will survive way into the future.